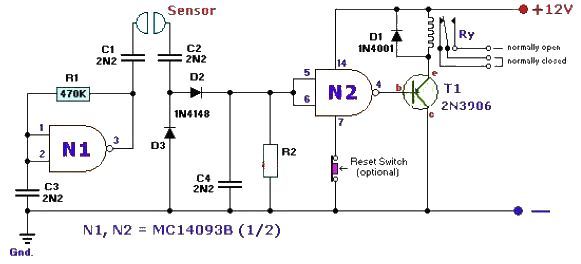

This is a capacitive sensor that utilized the fact that changes in liquid level alter the dielectric contant of plates attached to the fluid container when the plates are viewed as a capacitor.

Capacitive fluid level sensor circuit.

Fuel level washer fluid coolant level medical.

Rigid flex circuit allows the sensors to be placed on various shaped surfaces.

A second pair of capacitive sensors shown as c 2 is used as a reference.

Elobau a leader in the development of non contact sensors is currently prototyping a new capacitive level sensor.

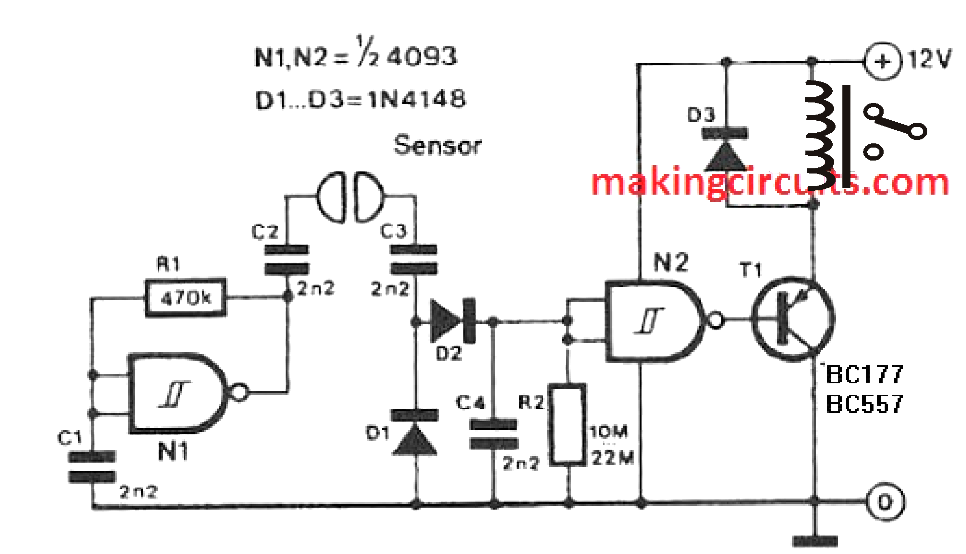

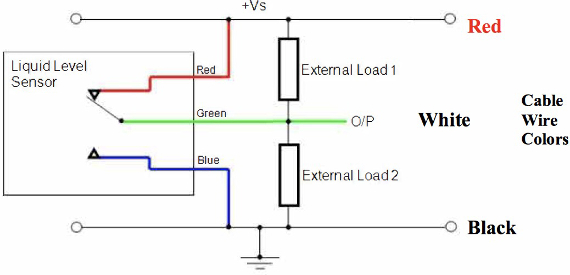

Shows how to create a simple liquid level sensor using only a single probe.

Capacitive fluid level sensor.

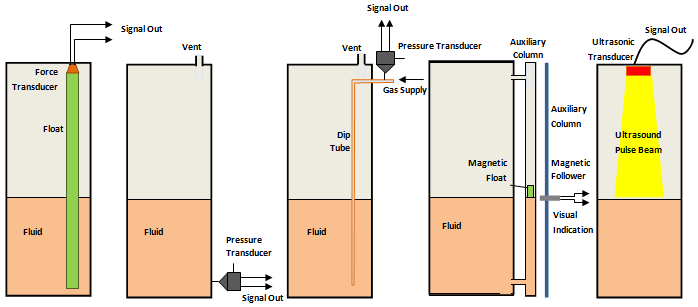

Demonstrating the working comparison of standard capacitive sensor and smart level capacitive sensor.

For the next spring i plan to make a fully automatic hydroponic setup.

International association of oil gas.

Since εr water εr air the capacitance of the sensor can be approximated by the capacitance of the submerged section.

Level is the length submerged into liquid.

The level capacitance can be simulated by entering the low and high level values.

Figure capacitance level sensor calibration.

This allows us to create a level sensor that is safe for use with any liquid this one will be used in a buggy with gasoline petrol.

Typically a standard capacitive sensor can be adjusted to disregard a wall.

Capacitance units will calculate automatically the capacitance variation image based in the factory calibration for a conductivity 100 μs cm.

A capacitive liquid sponsor relies on the fact the the capacitance or charge between 2 metal plates will change in this case increase depending on what material is between them.

Drug pens insulin pumps droplet.

The capacitive sensor can be made to be an integral part of a printed circuit containing electronic detection circuitry thereby making the device.

When standard capacitive sensors are used for liquid level detection in an indirect level detection application the sensor must be adjusted to the point where it ignores the container wall but reliably detects the capacitance change caused by the changing liquid level.

The sensor is designed for use in various tank level applications including food equipment and mobile fluid containers and medical.

Thus the level of the liquid can be calculated as c 1 c 2.

One of the things i need for automation is a water level sensor so.

While spring is over 6 months away from now it is pretty much autumn right now there is still plenty to do.