Sheetcam is a low cost but feature packed cam package.

Cam piercing sheet metal.

Both blanking and piercing are shearing operations.

Metal piercing piercing metal is a process used to provide holes slots and notches with tight tolerances within sheet metal or metal components.

You should only switch into new earrings after the suggested healing period.

Piercing is a metal forging technique that is often performed as an auxiliary process in conjunction with other forging processes in the manufacture of it can be used to create a cavity or hole in the work piece.

Terry march 27 2018 at 6 43 pm reply.

Piercing is the operation of punching holes in the sheet metal.

Piercing metal is a process used to provide holes slots and notches with tight tolerances within sheet metal or metal components.

Welcome to the sheetcam website.

This sturdy bit of wood with a v cut is extremely helpful for piercing sheet metal as it supports the metal on both sides of a cut.

As a result of applied force from the piercing tool sheet metal starts tearing and produces extruded hole slot.

Piercing operation produces an extruded hole or slot.

A minimum of 6 weeks for pierced ear lobes and 12 weeks for ear cartilage piercings.

Metalix software products provide a complete comprehensive cad cam solution which is friendly and easy to use.

Please try again later.

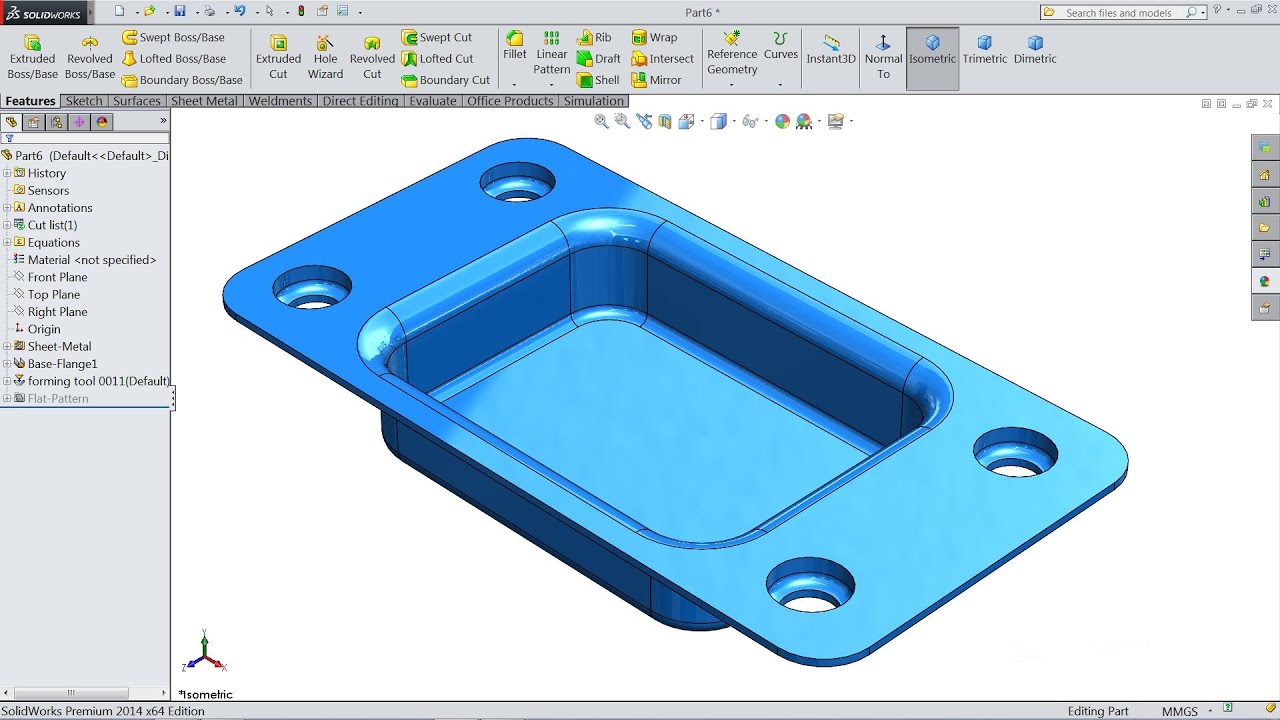

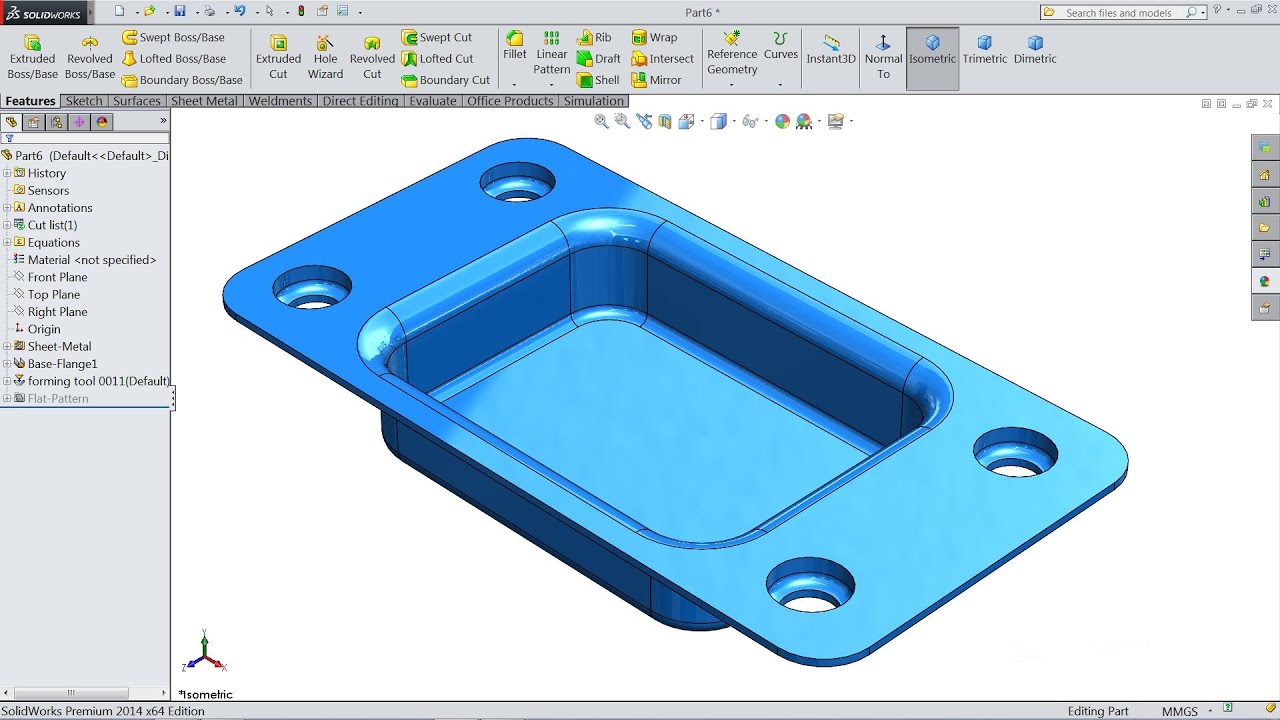

Piercing in sheet metal as explained in the above image.

Difference between blanking and piercing.

Piercing metal provides a clean cut and high output rates often making it a more productive method than drilling or using a laser.

Piercing metal provides a clean cut and high output rates often making it a more productive method than drilling or using a laser.

How long does it take an ear piercing to heal.

In case of piercing or punching the material which is cut out from the sheet metal is scrap and the reining material is the actual part.

This feature is not available right now.

Does not break through the metal s surface like a drilling operation.

Sheetcam is suitable for milling routing plasma waterjet laser and oxy fuel cutting.

Click on the features button to see some of sheetcam s features.

Additional modules are available for processing tubes and for.